by Debra Fiakas CFA

The looming threat of global warming has nearly everyone – except perhaps those bickering with each other in the Whitehouse – scrambling for lower carbon energy sources. Intermittancy remains a stumbling block for several of the lower-carbon renewable energy sources, particularly wind and solar energy systems. To be a serious contributor to grid-connected power systems these energy sources need utility scale batteries that can store energy when the sun is down or winds have died away. Unfortunately, with current technology the cost of such battery capacity increases the levelized cost of energy (LCOE) of renewable systems to an uncompetitive price tag.

As a refresher, LCOE is a measure of the average total cost to build and operate a power-generating asset over is lifetime relative to the total energy output over that lifetime, i.e. total costs divided by total output. Typically expressed as cost per kilowatt hour, it is handy for comparing different methods of electricity generation on a consistent basis. The more bells and whistles a system requires to produce power – and meet environmental standards – the higher the LCOE per kilowatt hour.

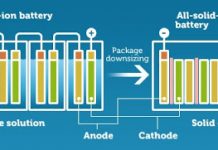

Let’s get back to those batteries that could help make wind and solar ‘grid-attractive’. Lithium ion batteries have been the most talked about battery storage technology in recent years. Unfortunately, lithium ion batteries do not have a particularly long useful life, lasting only a few hundred charge/recharge cycles. As a consequence, batteries using lithium ion technology could add as much as $0.33 per kilowatt hour to the LCOE for wind or solar power systems with a storage component.

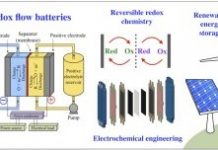

Flow battery technology is considered a viable alternative to lithium ion batteries for stationary power sources. Flow technology converts chemical energy into electricity by pumping electrolytes through a stack of electrochemical cells. First, as tested so far, flow batteries show promise for numerous charge/discharge cycles. Some flow batteries can last through as many as 10,000 cycles. Second, flow batteries rely on a fluid electrolyte that can be replaced, reducing the overall cost of operation. Thus it is expected that flow batteries will present a far lower LCOE contribution – a factor that makes it more appealing for wind and solar system operators.

There is a gaggle of developers with flow battery projects underway or with commercial-ready battery products. Vanadium has been the preferred material for several years and several vanadium-based storage systems are already in operation. Zinc bromide runs a close second. The most recent innovation is based on iron, which offers the benefits of better safety and lower operating cost. Iron-based flow batteries are also considered to be more environmentally friendly than those relying on strong acids like vanadium.

The next few posts will take a closer look at the utility-scale battery developers and producers.

|

Company Name

|

Symbol

|

Flow Technology

|

Status

|

|

American Vanadium

|

Vanadium

|

Commercial

|

|

|

Arotech (Electric Fuel Energy)

|

Iron

|

Development

|

|

|

Gildemeister (Cell Cube)

|

Private

|

Vanadium

|

Commercial

|

|

Energy Storage Systems

|

Private

|

Iron

|

Development

|

|

EnSync Energy Systems

|

Zinc bromide

|

Commercial

|

|

|

Imergy

|

Private

|

Vanadium

|

Commercial

|

|

Primus Power

|

Private

|

Zinc bromide

|

Development

|

|

RedFlow

|

Zinc bromide

|

Commercial

|

|

|

UniEnergy Technologies

|

Private

|

Vanadium

|

Commercial

|

|

Sumitomo

|

SSUMY: OTC

|

Vanadium

|

Commercial

|

|

Vionx Energy

|

Vanadium

|

Commercial

|

Debra Fiakas is the Managing Director of Crystal Equity Research, an alternative research resource on small capitalization companies in selected industries.

Neither the author of the Small Cap Strategist web log, Crystal Equity Research nor its affiliates have a beneficial interest in the companies mentioned herein.